Precision and Efficiency: CNC Machining of Automobile Mould Parts

2023-10-18

Introduction

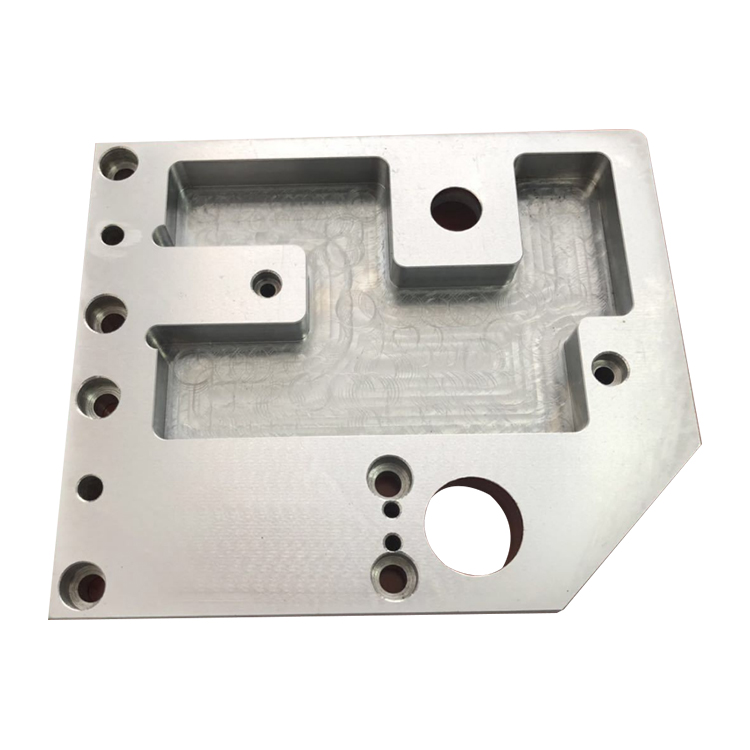

In the automotive industry, precision and efficiency are paramount when it comes to manufacturing high-quality components. CNC (Computer Numerical Control) machining has revolutionized the production of automobile mould parts, offering unparalleled accuracy, repeatability, and speed. From engine components to body panels, CNC machining plays a critical role in the production of complex and intricate mould parts. In this blog, we will explore the benefits and applications of CNC machining in the production of automobile mould parts and how it contributes to the overall efficiency and quality of the automotive manufacturing process.

1. Unmatched Precision and Accuracy

CNC machining is known for its exceptional precision and accuracy. The use of computer-controlled machines eliminates the potential for human error, ensuring consistent and reliable results. In the production of automobile mould parts, precision is crucial to guarantee proper fit and functionality. CNC machines can achieve tight tolerances and intricate geometries, ensuring that mould parts are manufactured to the exact specifications required. This level of precision ensures optimal performance and reduces the need for manual adjustments or modifications.

2. Versatility and Complexity

Automobile mould parts come in various shapes, sizes, and complexities. CNC machining offers unparalleled versatility to handle the production of different types of mould parts. From simple brackets and fittings to intricate engine components and body panels, CNC machines can accommodate a wide range of designs and materials. Whether it's milling, turning, or drilling, CNC machines can execute complex operations with ease, allowing for the efficient production of diverse mould parts required in automotive manufacturing.

3. Efficient and Consistent Production

CNC machining provides a high level of efficiency in the production of automobile mould parts. The automation of processes and the ability to run multiple operations simultaneously minimize production time and increase overall productivity. Once the CNC program is set, the machines can operate continuously, reducing the need for manual intervention and streamlining the manufacturing process. Additionally, CNC machining ensures consistent and repeatable results, eliminating variations that may arise from manual operations and ensuring that each mould part meets the required standards.

4. Cost-Effectiveness and Waste Reduction

CNC machining offers cost-effectiveness in the production of automobile mould parts. The precision and efficiency of CNC machines contribute to reduced material waste and optimized use of resources. CNC programs can be optimized to minimize material removal, resulting in less waste and lower material costs. Additionally, the ability to produce mould parts with high accuracy and minimal errors reduces the need for rework or scrap, leading to cost savings and improved overall manufacturing efficiency.

5. Flexibility and Adaptability

The automotive industry is characterized by rapid advancements and evolving designs. CNC machining provides the flexibility and adaptability needed to keep up with changing requirements. CNC programs can be easily modified to accommodate design changes, allowing for quick production of updated mould parts. This flexibility ensures that manufacturers can adapt to market demands and implement design improvements without significant disruptions to the production process.

Conclusion

CNC machining has revolutionized the production of automobile mould parts, offering unmatched precision, efficiency, and flexibility. From complex engine components to intricate body panels, CNC machines deliver consistent and high-quality results, ensuring optimal fit and performance. The ability to handle a wide range of materials and designs makes CNC machining an essential tool in the automotive manufacturing process. With its cost-effectiveness, waste reduction, and adaptability, CNC machining plays a vital role in the production of mould parts that meet the stringent requirements of the automotive industry. As technology continues to advance, CNC machining will continue to be at the forefront of automotive manufacturing, driving innovation and efficiency in the production of automobile mould parts.