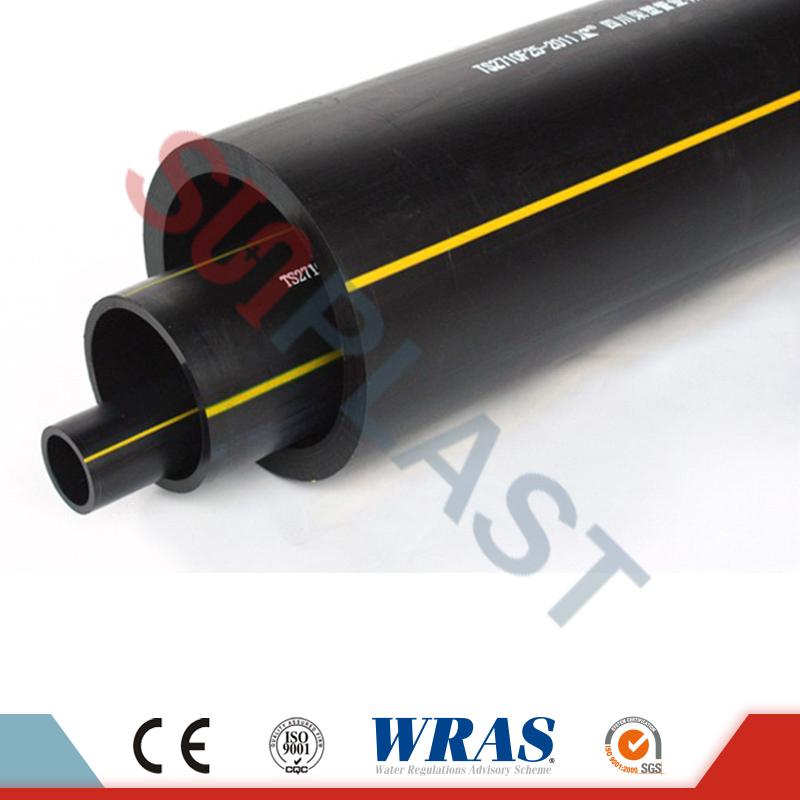

HDPE Pipe: The Versatile Choice for Outdoor Gas Distribution in Yellow Color

2023-10-18

Introduction:

When it comes to outdoor gas distribution systems, safety and reliability are paramount. HDPE (High-Density Polyethylene) pipe, specifically designed for gas applications, has emerged as a popular choice among professionals in the industry. With its exceptional properties, including durability, corrosion resistance, and flexibility, HDPE pipe offers a reliable solution for outdoor gas distribution. In this blog post, we will explore the benefits and features of HDPE pipe, particularly in its yellow color variant, for outdoor gas applications.

1. Understanding HDPE Pipe for Outdoor Gas Distribution:

HDPE pipe is a type of plastic pipe made from high-density polyethylene material. It is widely used in various industries due to its versatility, cost-effectiveness, and durability. HDPE pipe is particularly suitable for outdoor gas distribution systems due to its resistance to corrosion, flexibility, and ability to withstand harsh weather conditions.

2. Benefits of HDPE Pipe in Outdoor Gas Applications:

a. Corrosion Resistance: HDPE pipe exhibits excellent resistance to corrosion, making it ideal for outdoor gas distribution. Unlike metal pipes, HDPE is not susceptible to rust, decay, or chemical reactions, ensuring long-lasting performance and reducing the risk of leaks or failures.

b. Flexibility and Lightweight: HDPE pipe is known for its flexibility and lightweight nature, allowing for easy handling, transportation, and installation. The flexibility of HDPE pipe makes it highly resistant to cracking or breaking under stress, ensuring a reliable gas distribution system, even in areas with varying terrain or ground movement.

c. UV Resistance: Outdoor gas distribution systems are exposed to sunlight, which can degrade materials over time. HDPE pipe is designed with UV stabilizers, making it highly resistant to ultraviolet (UV) rays. This UV resistance helps maintain the structural integrity and performance of the pipe, even with prolonged exposure to sunlight.

d. Leak-Free Joints: HDPE pipe utilizes heat fusion techniques to create seamless and leak-free joints. This fusion process creates strong, continuous connections between pipes, eliminating the risk of leaks or gas seepage. The absence of joints and seals ensures a secure and reliable gas distribution system.

e. Longevity and Low Maintenance: HDPE pipe has a long service life, often exceeding 50 years, thanks to its durability and resistance to degradation. Its low maintenance requirements make it a cost-effective choice for outdoor gas distribution systems, reducing the need for frequent repairs or replacements.

3. Yellow Color for Outdoor Gas Distribution:

The use of yellow-colored HDPE pipe has become the industry standard for outdoor gas distribution systems. The yellow color serves as a visual indicator, distinguishing gas lines from other utilities such as water or telecommunications. It enhances safety by ensuring that individuals working near or around the gas lines can easily identify them, minimizing the risk of accidental damage or excavation.

The yellow color also complies with industry regulations and codes, providing a consistent and recognizable standard for gas distribution infrastructure. This standardized approach helps utilities, contractors, and emergency responders identify and differentiate gas lines quickly and efficiently.

Conclusion:

HDPE pipe in yellow color has emerged as a reliable and efficient solution for outdoor gas distribution systems. Its corrosion resistance, flexibility, lightweight construction, UV resistance, leak-free joints, longevity, and low maintenance requirements make it an ideal choice for gas applications. The yellow color serves as a visual identifier, promoting safety and compliance with industry standards. By utilizing HDPE pipe in yellow color, gas distribution systems can achieve reliable and efficient operation, ensuring the safe delivery of gas to homes, businesses, and industries.