Exploring the Importance of Dozer Carrier Rollers in Heavy Equipment

2023-10-18

Introduction

When it comes to heavy equipment used in construction and earthmoving projects, dozers stand out as some of the most powerful and versatile machines. They are vital for tasks such as grading, pushing material, and clearing land. While the dozer blade, engine, and tracks are key components, one often overlooked but crucial part is the carrier roller. In this blog, we will delve into the significance of dozer carrier rollers and their role in ensuring the smooth operation of these mighty machines.

Understanding the Basics

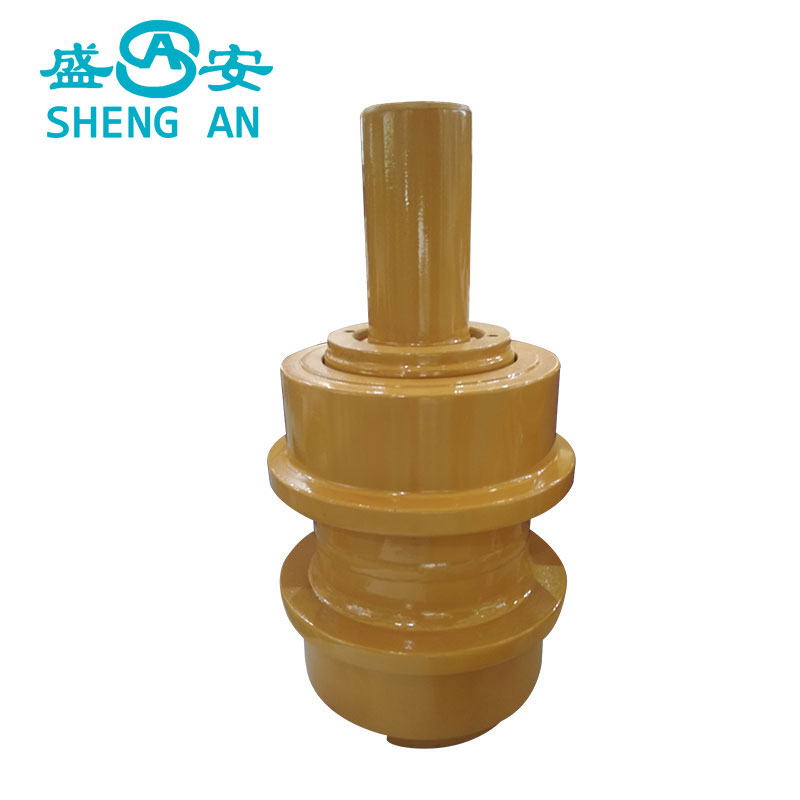

Before we dive deeper, let's clarify what a carrier roller is. Carrier rollers are a type of undercarriage component found on crawler dozers. They are situated on the top of the undercarriage frame and play a pivotal role in supporting and guiding the track chain.

1. Support and Weight Distribution: Carrier rollers bear a significant portion of the dozer's weight, which is essential for maintaining stability and balance during operation. They prevent excessive wear and stress on other undercarriage components, such as the track links and idlers.

2. Track Chain Guidance: Carrier rollers help guide the track chain along its path, ensuring it stays properly aligned with the sprocket and idler. This guidance prevents lateral movement of the track chain, which could lead to misalignment and increased wear.

3. Load Distribution: As the dozer moves over uneven terrain, carrier rollers adjust to the varying ground conditions. This dynamic load distribution minimizes the impact on the undercarriage and enhances overall performance and longevity.

The Impact of Carrier Roller Maintenance

Now that we understand the fundamental role of carrier rollers, let's discuss the importance of proper maintenance:

1. Extended Lifespan: Regular inspection and maintenance of carrier rollers can significantly extend their lifespan. This not only reduces operating costs but also minimizes downtime due to unexpected breakdowns.

2. Improved Performance: Well-maintained carrier rollers ensure that the track chain operates smoothly. This contributes to better dozer maneuverability, increased traction, and enhanced overall performance.

3. Cost Savings: Neglecting carrier roller maintenance can lead to premature wear and damage to other undercarriage components. Replacing these parts can be expensive, making preventive maintenance a cost-effective choice in the long run.

4. Safety: A worn or damaged carrier roller can compromise the stability of the dozer, potentially leading to accidents. Regular maintenance helps ensure safe working conditions for operators and everyone on the construction site.

Conclusion

In the world of heavy equipment, every component plays a vital role in ensuring the efficient and safe operation of machines like dozers. Carrier rollers, although often overlooked, are critical to maintaining stability, distributing weight, and guiding the track chain. By understanding their importance and implementing proper maintenance practices, construction companies can maximize the lifespan of their dozer undercarriages, reduce operating costs, and ultimately improve job site productivity.

Incorporating a proactive approach to dozer carrier roller maintenance not only benefits the bottom line but also contributes to a safer and more efficient work environment. So, the next time you see a dozer in action, remember the unsung hero working quietly beneath it—the carrier roller.