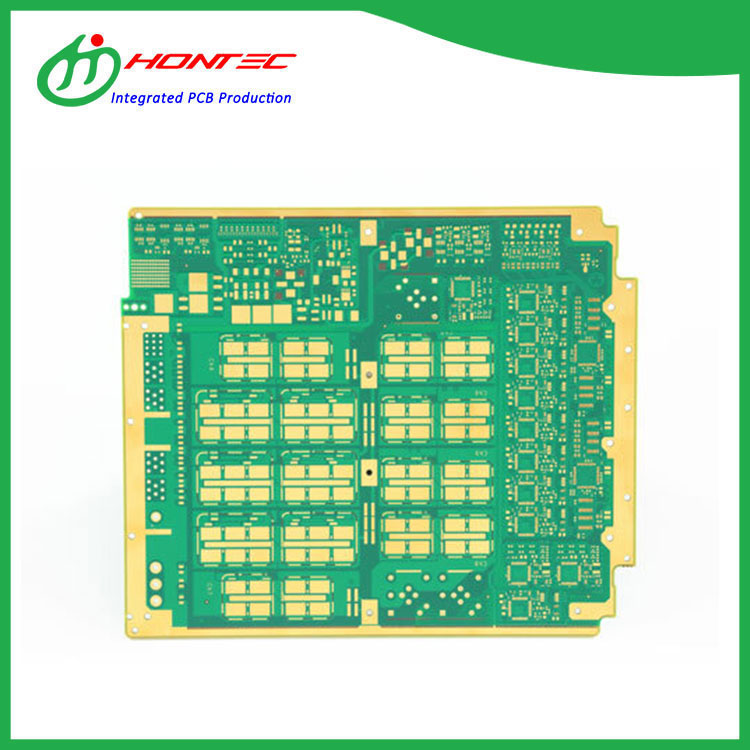

Navigating the Challenges of Designing Multilayer Boards

2024-05-24

When it comes to the design of multilayer boards, there are numerous complexities and potential challenges that can arise. These boards, often used in advanced electronic devices, require precision, expertise, and a keen eye for detail. Here are some of the common challenges faced during the design process:

1. Thermal Management

One of the primary challenges in multilayer board design is thermal management. As components become more dense and powerful, heat generation becomes a significant concern. Designers must carefully consider heat dissipation paths and utilize materials with good thermal conductivity to ensure the board operates within safe temperature limits.

2. Electrical Considerations

Electrical properties are crucial for ensuring signal integrity and performance in multilayer boards. Designers must take into account impedance matching, crosstalk, and noise issues that can arise due to the close proximity of traces and components. Proper routing and grounding techniques are essential to minimize these effects.

3. Layer Stack-Up

The layer stack-up of a multilayer board determines the placement and order of the various conductive layers. This can be a complex task, as it requires balancing the needs of different components and signal types. The stack-up must be designed to optimize electrical performance while minimizing crosstalk and ensuring adequate spacing between traces.

4. Routing Complexity

Routing traces on a multilayer board can be challenging due to the limited space and the need to avoid interference with other components. Designers must carefully plan the routing paths, taking into account the size and placement of components, as well as the board's overall layout. The use of vias and blind vias can help reduce routing complexity but also adds another layer of design complexity.

5. Manufacturing Constraints

The manufacturing process for multilayer boards has its own set of constraints that can impact the design. These include limitations on the number of layers, minimum trace widths and spacings, and the availability of certain materials. Designers must work closely with manufacturers to understand these constraints and design boards that can be successfully produced.

6. Component Placement

Component placement on a multilayer board is a critical aspect of the design process. The placement of components must be optimized to minimize crosstalk, interference, and heat generation while still allowing for adequate routing space. The use of advanced CAD tools and simulation software can help designers visualize and optimize component placement.

7. Cost Considerations

Cost is always a consideration in any design project. Multilayer boards can be expensive, depending on the number of layers, materials used, and manufacturing complexity. Designers must carefully balance the need for performance and reliability with cost constraints to ensure the final product meets the budget requirements.

In conclusion, designing multilayer boards requires a deep understanding of electronics, thermal management, and manufacturing processes. Navigating the challenges associated with these boards requires precision, expertise, and a commitment to continuous improvement. By understanding and addressing these challenges, designers can create multilayer boards that meet the demanding requirements of today's electronic devices.