Balancing Act: Environmental Impact and Sustainability of Petroleum Resin Production and Use

2024-03-18

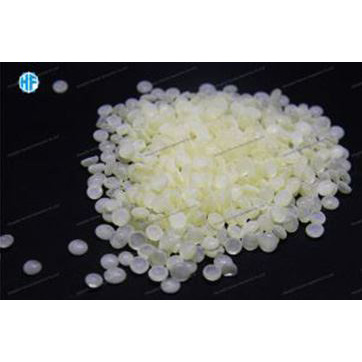

Petroleum resin, a versatile synthetic resin derived from petroleum feedstocks, plays a crucial role in various industries due to its unique properties and applications. However, like many petrochemical-based materials, petroleum resin production and use raise important environmental and sustainability considerations. In this blog, we'll delve into the environmental impact of petroleum resin production and explore sustainability considerations associated with its use, highlighting challenges and opportunities for mitigating environmental harm and promoting sustainable practices.

Environmental Impact of Petroleum Resin Production:

1. Greenhouse Gas Emissions:

The production of petroleum resin involves energy-intensive processes, including refining, polymerization, and distillation, which contribute to greenhouse gas emissions. Carbon dioxide (CO2) emissions from fossil fuel combustion and methane (CH4) emissions from industrial processes contribute to climate change and global warming.

2. Air Pollution:

Petrochemical manufacturing processes emit air pollutants such as volatile organic compounds (VOCs), nitrogen oxides (NOx), and sulfur dioxide (SO2), which can contribute to smog formation, respiratory ailments, and environmental degradation. Emissions from petroleum resin production facilities may impact air quality in surrounding communities.

3. Water Pollution:

Discharges of wastewater and chemical effluents from petroleum resin production facilities may contain contaminants such as heavy metals, organic solvents, and toxic chemicals, posing risks to aquatic ecosystems and water quality. Accidental spills or leaks during transportation and storage can further exacerbate water pollution.

4. Resource Depletion:

Petroleum resin production relies on finite fossil fuel resources, including crude oil and natural gas, which are subject to depletion and environmental degradation associated with extraction, transportation, and refining processes. The unsustainable use of non-renewable resources raises concerns about long-term resource availability and energy security.

Sustainability Considerations in Petroleum Resin Use:

1. Alternative Feedstocks:

Exploring alternative feedstocks and renewable resources for resin production, such as bio-based feedstocks derived from plant materials, agricultural residues, or waste biomass, can reduce reliance on fossil fuels and mitigate environmental impact. Bio-based resins offer potential benefits in terms of carbon neutrality, biodegradability, and renewable sourcing.

2. Circular Economy Practices:

Implementing circular economy principles, such as recycling, reuse, and resource recovery, can reduce waste generation and promote resource efficiency in petroleum resin use. Designing products and packaging for recyclability and incorporating recycled content into resin formulations can minimize environmental footprint and promote closed-loop systems.

3. Energy Efficiency and Emissions Reduction:

Improving energy efficiency and adopting cleaner production technologies in petroleum resin manufacturing processes can reduce greenhouse gas emissions and air pollutants. Investing in renewable energy sources, process optimization, and emission control measures can enhance environmental performance and sustainability.

4. Life Cycle Assessments:

Conducting life cycle assessments (LCAs) to evaluate the environmental impacts of petroleum resin production and use across the entire product life cycle can inform decision-making and identify opportunities for environmental improvement. Assessing factors such as energy consumption, emissions, resource utilization, and end-of-life management can guide sustainable design and procurement strategies.

Collaborative Efforts and Innovation:

1. Industry Collaboration:

Collaborative initiatives among industry stakeholders, government agencies, academia, and non-governmental organizations (NGOs) can drive innovation, research, and development efforts aimed at advancing sustainable practices and technologies in petroleum resin production and use. Sharing best practices, knowledge exchange, and pre-competitive collaborations can accelerate progress towards sustainability goals.

2. Regulatory Frameworks:

Regulatory frameworks, standards, and policies play a crucial role in promoting environmental protection and sustainability in the petrochemical industry. Implementing regulatory measures such as emission controls, pollution prevention, and product stewardship requirements can incentivize compliance and drive continuous improvement in environmental performance.

Conclusion:

The environmental impact and sustainability considerations associated with petroleum resin production and use underscore the need for holistic approaches to mitigate environmental harm and promote sustainable practices. By adopting alternative feedstocks, embracing circular economy principles, improving energy efficiency, conducting life cycle assessments, and fostering collaboration and innovation, stakeholders can work towards reducing the environmental footprint of petroleum resin and advancing towards a more sustainable future. As global awareness of environmental issues grows, integrating sustainability into the petrochemical industry becomes increasingly essential for safeguarding ecosystems, protecting human health, and ensuring long-term prosperity.